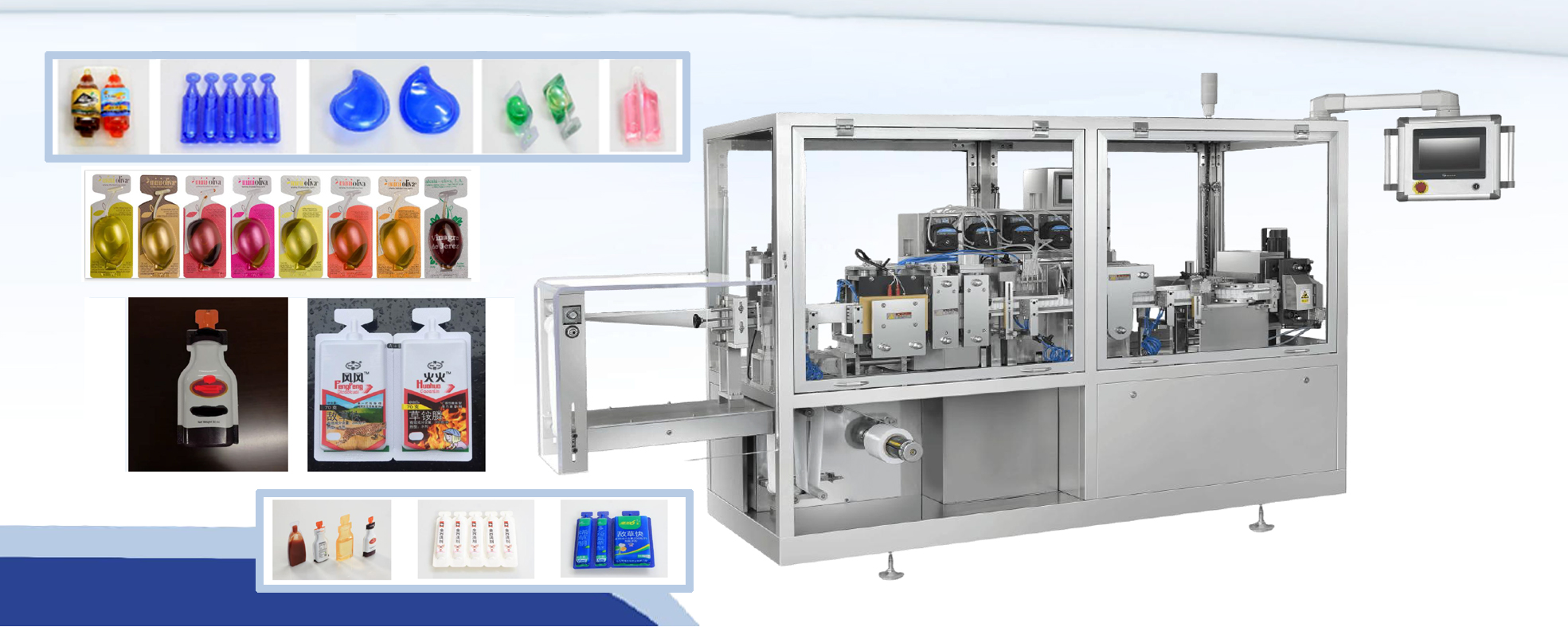

BFS & FFS Technologies

Discover our advanced Blow-Fill-Seal and Form-Fill-Seal technologies. BFS machines excel in sterile products and represent more advanced technology, while FFS machines are perfect for monodose pharmaceuticals. Both technologies have a great future in sterile and unidose products.

Choose Your Technology

We offer two distinct technologies to meet different pharmaceutical packaging needs. Both represent the future of pharmaceutical packaging with great potential in sterile and unidose products.

For Sterile Products & Advanced Technology

Blow-Fill-Seal technology represents the most advanced solution for sterile pharmaceutical packaging. Perfect for injectable solutions, ophthalmic products, and other sterile applications requiring the highest level of contamination control.

For Monodose Pharmaceuticals

Form-Fill-Seal technology specialized for monodose pharmaceutical applications. Ideal for single-dose medications, oral solutions, and any pharmaceutical requiring precise individual dosing for improved patient compliance.

BFS vs FFS: Choose the Right Technology

Both technologies represent the future of pharmaceutical packaging, each optimized for specific applications and requirements.

Best For:

- • Injectable solutions and vaccines

- • Ophthalmic products (eye drops)

- • Sterile irrigation solutions

- • High-value sterile pharmaceuticals

Key Advantages:

- • Ultimate sterility assurance

- • Most advanced technology available

- • Integrated container formation

- • Future of sterile packaging

Best For:

- • Oral liquid medications

- • Pediatric formulations

- • Hospital single-dose medications

- • Nutritional supplements

Key Advantages:

- • Perfect monodose accuracy

- • Improved patient compliance

- • Reduced medication waste

- • Future of unidose products

Ready to Embrace the Future of Pharmaceutical Packaging?

Contact Target Co. today to discuss which technology - BFS for sterile products or FFS for monodose applications - is right for your pharmaceutical manufacturing needs.